MODİ İNTERNATİONAL

Earthquake Resistant Environment Friendly Building Systems

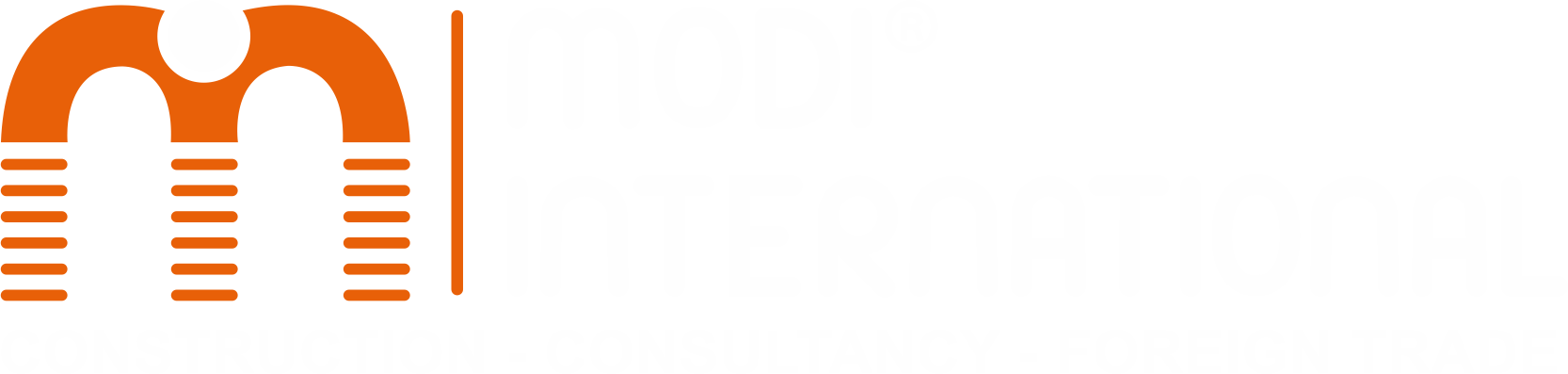

Modi Panel System brings a new approach to construction systems by building fast, sustainable, and earthquake-resistant structures. In line with this vision, it ensures time savings and the construction of earthquake-resistant buildings by providing structural elements through prefabricated production. This system, which requires fewer workers, also lays the groundwork for the creation of new job sectors in the construction industry.

In addition, a training program will be developed for the introduction and application of this innovative product, aiming to establish a certified training platform for architects and engineers nationwide. This approach will lead the way to a broader field of education and expertise within the construction industry.

Developed in Australia in the 1990s, this system is preferred in various projects due to its rapid application capabilities. It offers economic advantages by increasing efficiency, especially when used in mass housing projects.

The recyclable plaster material makes this system sustainable, while the fire resistance and waterproofing properties of the plaster panels deliver high performance. The modular design feature allows for the construction of high-performance buildings at lower costs, especially in social housing projects.

The steady increase in construction material and labor costs, along with the need to prevent a reduction in investors’ profit margins, necessitates the acceleration of the construction process.

Traditional building methods and materials are not capable of meeting this demand.

- The idea of shortening the timeline by building rapid walls was conceived

Rapid walls are produced from abundant and inexpensive natural resources, and then transformed into homes and apartments.

Modi Panel walls are load-bearing, fire-resistant wall panels made from factory-produced glass fiber-reinforced gypsum. A single 12m x 3m panel can be installed on-site in 15 minutes, replacing 1800 bricks.

GENERAL OVERVIEW – WALL FEATURES

- Lightweight – 40kg/m²

- Load-bearing capacity of 890kN/m – suitable for buildings up to 15 stories

- Fire rating of 240 minutes (4 hours)

- Waterproof

- Pest-resistant

- Earthquake-resistant

- Environmentally friendly

- Quick installation with minimal equipment, tools, and training required.

ADVANTAGES OF THE WALL PRODUCT

- Panels are produced through a casting process under controlled conditions.

- Delivered ready for installation to the construction site, significantly reducing construction time.

- Has load-bearing capabilities suitable for use in single, double, or multi-story buildings.

- Easily adaptable to desired architectural styles

- The weight of the structure is reduced by up to 50%, further decreasing seismic loads.

- Panels carry loads from the moment of installation and can be immediately loaded with the floor structure above.

The amount of detailing required during the design and construction phases of the project is minimized.

The panels are manufactured by pouring into horizontal casting tables.

The process is computer-controlled and adjusted based on the properties of local raw materials.

The result is a load-bearing panel with consistent physical characteristics.

The panels are cut in the factory using a 12-head, computer-controlled saw.

The panels are cut in the factory using a 12-head, computer-controlled saw. - Cutting tolerances can be programmed to as precise as 0.5 mm.

- This significantly reduces the need for measurements on the construction site.

Modi International typically transports 5-8 panels stacked and ready for installation to the construction site.

Modi International typically transports 5-8 panels stacked and ready for installation to the construction site. - Alternatively, they can be transported in open-top containers.

- For handling during transportation and installation, the panels are processed using purpose-designed lifting jaws.

First Licensed Building in Turkey

Located in Celaliye – Büyükçekmece – Istanbul

“The Modi International Company Building.”